Will Solid-State Batteries Revolutionise Electric Cars & How it Improves Public EV Charging?

Solid-state batteries have long been touted as the next big leap in electric vehicle (EV) technology, promising smaller, lighter, and safer batteries with faster charging capabilities. Now in 2025 we are seeing the first commercial vehicles become available. So, what makes solid-state batteries so promising, and how close are we to seeing them in cars?

What Are Solid-State Batteries?

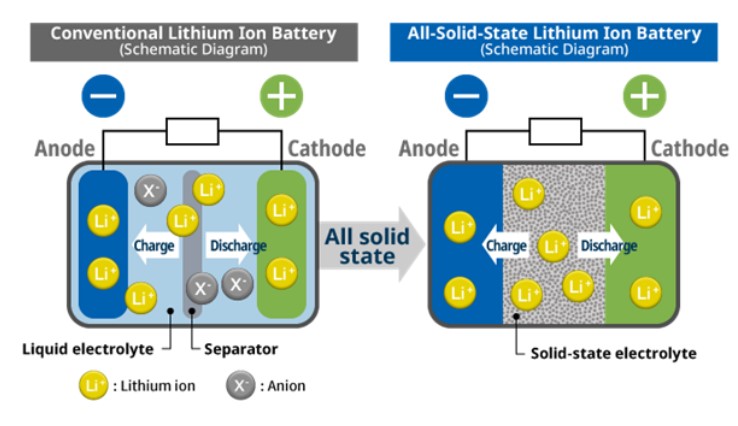

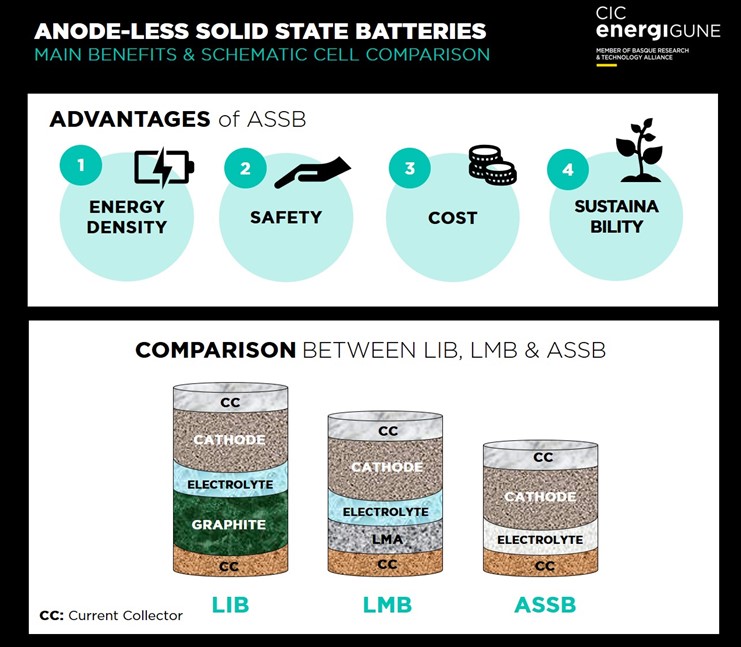

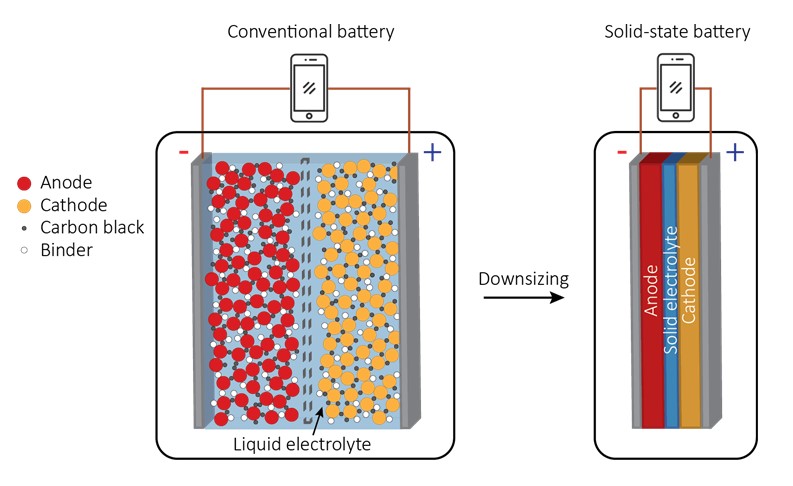

Though solid-state batteries are a type of lithium-ion battery, they differ primarily in their electrolyte. Instead of using a liquid or gel electrolyte, they employ a solid material, often a glass ceramic or plastic polymer. This solid electrolyte allows for a thinner separator between the battery’s anode and cathode, resulting in a lighter, more compact design—an important improvement over current lithium-ion batteries that tend to be bulky and heavy.

The Benefits of Solid-State Batteries

The key advantage of a solid-state battery lies in its ability to transfer electrons more quickly. This enables faster charging and the potential for significantly higher energy storage. In practical terms, this could mean that EVs could gain hundreds of kilometers of driving range in just 10 minutes of charging. Automakers like MG have even suggested that solid-state batteries could support ranges of up to 1000 km per charge.

Beyond range, the increased energy density of these batteries could allow for smaller, lighter battery packs. This would help reduce the cost of EVs, which are often more expensive due to the high price of their battery packs. Smaller batteries could also open the door to easier electrification of larger vehicles like four-wheel drives and utility trucks, which require long ranges for towing and off-road driving.

This electricfication of commercial vehicles will mean that the days of only back to depot vehicles being electric will end. Interstate and high utilisation vehicles will be able to travel 500+ km on a single charge and require major infrastructure to support.

How Public EV Charging is Improved

Improving EV charging with longer-range batteries allows the driving experience to be similar to petrol with less frequent charging.

- Faster Charging: With solid state batteries, charging will be much quicker for a full charging session and that means less time waiting at the public charging station.

- Increased Confidence: Combining long-range batteries with reliable charging infrastructure reduces range anxiety, encouraging more people to switch to EVs.

- Sustainable Growth: A stronger charging network is vital to keep up with the growing number of EVs on the road.

Enhanced Fire Safety with Solid-State Batteries

Safety is another major selling point for solid-state batteries. Lithium-ion batteries are often talked about for their risk of thermal runaway—where a battery fire can intensify as it generates its own oxygen. This risk arises from the liquid electrolyte in lithium-ion batteries, which is highly flammable. If you want to know more, watch our video on EVs and fire safety.

In contrast, solid-state batteries use a solid electrolyte, which significantly reduces the risk of leaks and thermal runaway. This makes them inherently safer, especially as the EV market continues to grow and battery-related safety concerns remain a hot topic.

While fires from lithium-ion batteries are uncommon, automakers incorporate protective casings and safety measures to reduce the risk. However, when fires do occur, they can be intense and challenging to put out, often requiring thousands of gallons of water. Developing electric vehicles that are fire-resistant would be a significant benefit for drivers, communities, and fire departments.

The Challenges to Mass Adoption

While the potential for solid-state batteries is clear, their widespread use in electric vehicles is still years away. One of the primary hurdles is the high cost of manufacturing these batteries. Due to the complexity and novelty of the technology, solid-state batteries are still more expensive to produce than traditional lithium-ion batteries. This is a critical issue, considering that batteries are the most expensive component in an EV.

Scaling up production is also a significant challenge. While solid-state batteries are already in use in some niche applications, mass production for EVs is still a long way off. Dr. Adam Best, a principal research scientist at CSIRO, notes that the challenge isn’t in manufacturing the batteries themselves but in scaling production to meet the high demand of the EV market.

Temperature Sensitivity and Longevity Concerns

Another hurdle is the temperature sensitivity of solid-state batteries. In early prototypes, these batteries performed optimally only at elevated temperatures of 50-60°C. This could necessitate onboard heating systems, which would reduce the vehicle’s overall efficiency. Alternatively, improving the chemistry of these batteries to function effectively at ambient temperatures is an ongoing area of research—one that requires significant investment.

Additionally, solid-state batteries need to prove their longevity. Most consumer electronics with solid-state batteries may last just a few years, but EVs are expected to remain operational for decades. Toyota has recently made strides in solving the issue of cracks forming between the cathodes and anodes during repeated charge and discharge cycles, a problem that can degrade battery performance over time. By developing crack-resistant materials, Toyota believes it can achieve long-lasting solid-state batteries—though these solutions are still in the testing phase.

Other Battery Technologies

While solid-state batteries hold enormous promise, other battery technologies continue to evolve as well. Current lithium-ion batteries use either nickel manganese cobalt (NMC) or lithium iron phosphate (LFP) chemistries. LFP batteries, which are cheaper to manufacture but offer lower energy density, are gaining popularity, particularly in lower-cost EV models.

In addition, researchers are exploring alternative options like sodium-ion batteries, which are less expensive but come with lower energy density. CATL, one of the largest battery manufacturers in the world, has even announced a semi-solid battery using a new type of electrolyte to boost energy density. These developments highlight the intense focus on improving battery technology across the industry.

Looking Ahead

The race to develop better, safer, and more affordable batteries for electric vehicles is intensifying, and solid-state batteries remain a key focus of research and innovation. While we are still a few years away from seeing solid-state batteries in mass-market EVs, the advancements in energy density, safety, and efficiency suggest they could revolutionize the industry by the end of the decade. For now, automakers are also exploring other alternatives, including LFP and sodium-ion batteries, ensuring that the future of EVs will be powered by a diverse range of technologies.