Charging Solutions for Electric Bus Fleets

Transit solutions that rely on electric mobility are in high demand. Australia’s fleet of largely gas-driven buses is being transitioned to electric motors fuelled with what EVSE hopes is green energy.

But Why Electric Buses?

It’s simple – if you could replace a standard bus motor with an electrical motor without local emissions? If the buses could be manufactured in Australia? If the running costs over 25 years are lower? If all three answers are YES, we’re at the start of Australia’s journey.

Electric buses also avoid burning fossil fuels for energy. When the battery is charged using electricity from renewable energy sources, they operate practically emission-free. This is highly beneficial for the environment, air quality, and passengers.

However, switching to electric buses imposes changes on familiar processes for most. Therefore, it’s a good idea to consider the operations as a whole and rethink them completely. During the planning process, it is worth taking a close look at:

- Transit line planning

- Vehicle schedule planning and downtime

- Charging station requirements

- Charging power and energy supplies

Many experts today recommend charging vehicles at a central depot, primarily or entirely. This allows the amalgamation of charging assets and infrastructure into one cost rather than route-based charging. While it’s also possible to set up charge points along the routes, this can lead to extended construction efforts when the bus routes change in the future.

Sophisticated modelling by EVSE Australia and smart systems also provide further advantages, including charging with solar electricity, procurement of the least expensive energy for charging via time-of-day pricing, and in the future, the possibility for power supply companies to integrate Vehicle to Grid technology.

Electric Bus Fleets Around the World – Who’s On Top and Where is Australia?

China is showing what is possible: 400,000 electric buses are already on the road, this is approximately 14% of the total Chinese fleet. Currently, Australia is falling behind with about 23 Electric buses.

But don’t fear! Within the next five years, Australian cities and municipalities plan to purchase more than 1000 electric buses.

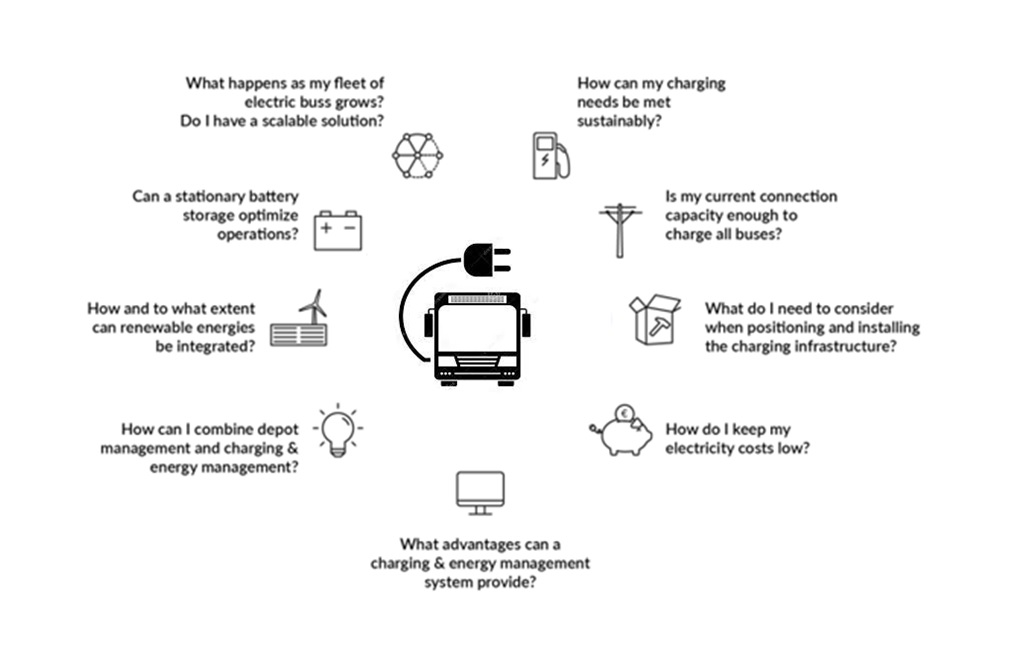

Bus charging ecosystems replace petroleum. This means you will need sufficient charging infrastructure for your fleet operation.

However, it’s unwise to throw something together when building your charging solution. There are important questions that need to be answered ahead of time – good planning saves significant costs and increases the availability of your electric buses.

Depot Bus Charging

Electric buses are charged at the depot, usually with a plug-in system, i.e., the electric bus is connected to a charging station with a cable.

Charging via induction or a pantograph is also possible. Charging is done overnight or during extended idle periods. Understanding the time and distance a bus drives can help reduce the costs of charging as through OCPP charging software such as Exploren OCPP. This allows you to schedule and manage the time and duration of charge to reduce costs.

Interval charging Electric buses are not charged at the depot but rather in transit, e.g. at the final stations or stops. Pantographs which are inductive charging stations or docking systems are used for this. Interval charging is perfect for electrifying long stretches, but the disadvantage is that the window for charging is short, meaning high charging power is needed. This is expensive and requires major electrical infrastructure.

Charging Power and Times

The speed of charging a bus also depends on the type of charging. In general, batteries are charged with direct current (DC). Alternating current (AC) in the power circuit needs to be converted with a rectifier.

In DC charging, there is a large rectifier in the charging station, which makes greater charging power possible and thus shorter charging times. Buses are usually charged using DC charging stations because they can be ready for service faster. The efficiency factor, battery status, temperature, and battery age also influence the time needed for charging. In general, the condition and life of the batteries are not necessarily worsened by charging. Using smart charging logic normally contributes to longer EV battery life though. At the same time, a state of charge (SoC) of 100% is not recommended for optimal usage.

General Electrical Costs

Electrical costs for industrial and commercial customers are comprised of three components:

Energy costs:

The energy costs are accrued from the actual consumed energy (kWh). These rates ($/kWh) differ based on the time of use during the day. In such cases, it can be a good idea to charge electric buses during periods when energy is cheap.

Grid Usage Fees:

Grid usage fees (network charges) are accrued from the use of the power grid. The amount of the grid usage fees is determined by the volume price ($/kW/a), calculated according to the highest volume used.

In other words, whoever uses high volumes from the grid pays more. High peak loads are expensive and therefore should be avoided. This is where charging and energy management can help. Metering and billing charges are also included in the network charges.

Prevent Load Peaks:

Load management lowers expensive peak loads and, as a result, reduces the costs of grid connection fees. Loads are balanced intelligently by temporally offsetting vehicles or charging them at lower capacities in favour of others. A charging management system is often necessary for charging several buses on the existing grid connection. Incorporating the cycle data, battery state of charge (SoC), energy requirements, desired pre-conditioning settings, and other factors allow you to precisely optimise the charging process for your operations.

Dynamic load management is required when there’s a tight margin on the available electrical power capacity for charging your electric buses.

Do you have electrical consumers at your location that require very high capacities on a short-term basis? A dynamic load management system might be the solution because it considers all the electricity consumers on-site.

For example, if your depot has a washing facility for the vehicles, a dynamic load management system reduces the charging power during washing to avoid overloading the power connection. This is possible by integrating a smart meter into the system, which continuously provides information about the power being drawn, which the charging stations can then interpret and alter their charging rates to accommodate.

For more information about the considerations and opportunities for charging solutions for electric bus fleets, download our Heavy Vehicle Fleet Electrification White Paper here.

Got more questions about bus charging? Get in touch with the EVSE team via [email protected] or 1300 406 210.